But don’t worry -- we’ll break this process down for you and address everything from how efficient inventory transfers work to implementing a software system that helps manage them.

Whether you’re a booming startup or an established business working to get the most beneficial systems in place, you’ll learn how to avoid costly mistakes and set your retail store up for success as you continue to grow.

The Basics of Inventory Transfers

Before we get into the details, here are some key terms to help you understand all of the moving parts involved in inventory transfers.Inventory

comprises all of the business’s assets, from the equipment and materials used to create products, to the shelves, display cases, and cash registers in your store.

Stock

is what a business actually sells to customers. For example, in a hair salon, hair products for sale would be stock -- while the styling chairs and hair dryers would be inventory. In a retail clothing store, shirts and dresses would be stock, while hangers and mirrors would be inventory.

When it comes to managing inventory and stock, inventory is usually counted once a year. As you can imagine, it’s not really necessary to regularly count the number of shelves in your store or raw materials used to make your goods. On the other hand, stock is tracked daily, since stock is what’s directly driving revenue for your business -- and it’s essential to keep a finger on the pulse of your regular sales activity.

An

inventory transfer

, or warehouse transfer, is when goods are transported from one warehouse location to another. It usually works like this:

- Determine the quantity of inventory you want to move and where you want to move it.

- Record key information about the inventory transfer, including its SKU, quantity being transferred, status, and category.

- Pack the transfer at the first warehouse.

- Ship the transfer.

- Receive the transfer at the second warehouse.

- Update the information about the transfer in your records.

Managing Inventory Transfers

Several factors play into the efficiency of managing your inventory. The layout of your warehouse, the positioning of items on shelves, and even the placement of barcodes on boxes can all impact how effectively you and your employees can work with inventory. A growing business will need to develop efficient processes before managing inventory gets out of hand.However, all of this becomes even more complex when you’re working with multiple warehouses and managing transfers between them. Here are the top challenges involved in inventory transfers, and what you can do to solve them.

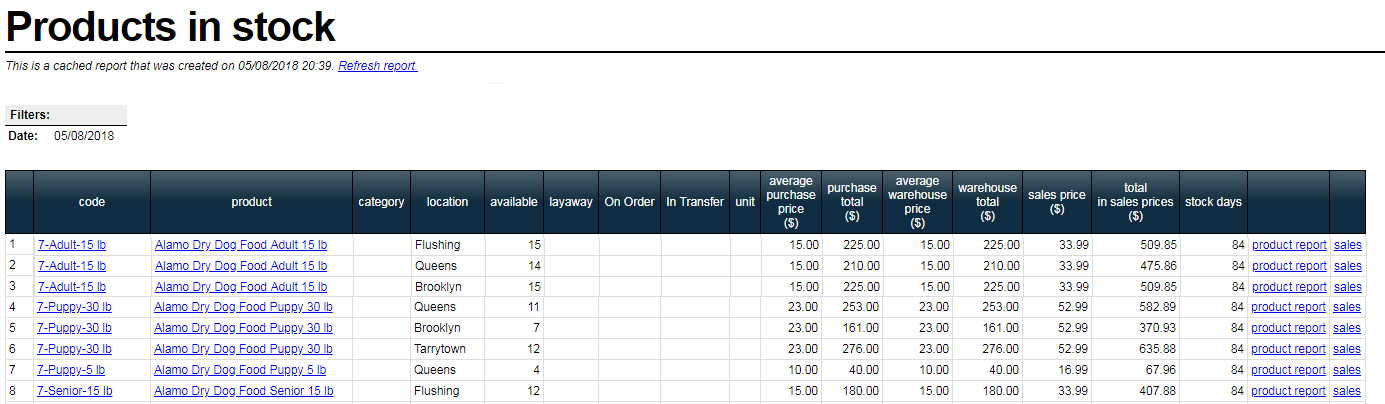

Communicating across different warehouses

Miscommunications are one of the most common problems when it comes to inventory transfers. Knowing what is being transferred, what was lost or damaged in transit, and when inventory will arrive can be difficult to track across multiple locations. In addition, if you’re using manual processes or don’t have access to a real-time view of inventory activity, this will inevitably cost your business time and money.How to improve warehouse communication:

Cloud-based software that syncs in real time across your different locations ensures reliable communication and improves scalability. You can get the full picture of what was moved, how much, when, where, and any other pertinent information you want to include. This removes guesswork and human error.

Automation is key to a smooth management workflow and can help eliminate miscalculation oversights. Erply’s back office adapts to any changes in real-time and will account for shipping time, transfer costs, and zip code-based tax rates. Say you have physical stock at a warehouse but it’s currently on reserve for a large order. Erply will notify you if any discrepancies occur so you can proactively order items from suppliers. A growing business that is overwhelmed with keeping track of new processes across multiple locations can use inventory management software to ease into the transition. Because Erply is cloud-based, all of your business’ information is stored in the back office, eliminating the need for stores to talk to one another.

Inventory management systems need to be comprehensive enough to meet your specific business needs. Erply is able to differentiate between items in stock and items available. Erply’s two-step inventory management system gives businesses more control over how they manage inventory transfers. A two-step inventory transfer enables a business to move items with transfer orders, which puts them on layaway. From there, the items can be sent to their destination location with a warehouse transfer. Using a two-step transfer process gives business owners more visibility into transfer process and cost of transfers.

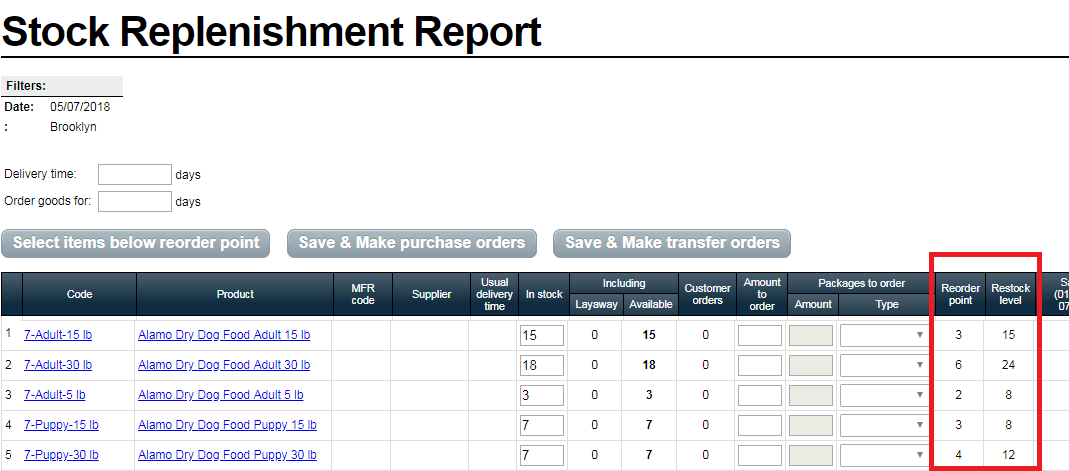

Managing minimum and maximum quantities

If you aren’t tracking minimum and maximum quantities in a reliable way, each of your locations is at risk of overstocking or losing out on sales due to understocking. How to better manage min/max levels:

Set up maximum and minimum quantities for every item in stock, and use set alerts to notify you when you’re close to running out of stock of each item. If you use a cloud-based solution, you can track inventory levels across multiple locations -- that way you’ll always know what’s at risk of being overstocked or understocked, and can plan your inventory transfers accordingly.

If you are struggling with how to manage min/max levels for your growing business, finding an ERP solution might be exactly what you need. In Erply’s back office, you can view product minimum and maximum levels across all store locations. Erply will even suggest inventory totals for you depending on the minimum and maximum levels across all store locations. Suggested totals roll up or down based on current reorder levels, so your inventory management is as accurate as possible.

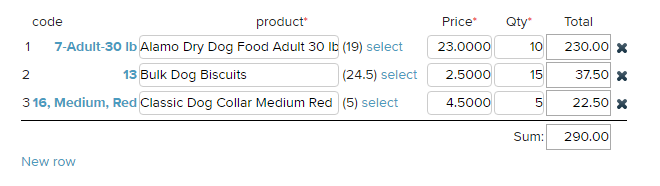

Managing purchase orders

If you have multiple store locations, you may have different protocols for purchasing orders at each location -- and transferring inventory thereafter. But when purchasing orders are siloed in this way, with no big-picture view of inventory levels across all locations, you’ll often wind up overspending and missing out on bulk deals from suppliers. How to track multiple purchase orders:

Opt for centralized purchasing (combining separate purchase orders into one central purchase order). When you purchase at volume for all of your locations, you’ll get better deals from suppliers, save on overhead, and improve inventory control. It’s vital for large businesses to find an effective way of managing multiple purchase orders and for growing businesses to develop strong management habits. You might be wondering how you can make managing purchase orders more efficient. Cloud-based retail software can streamline this process by giving you a bird’s eye view.

With software like Erply, you can complete centralized inventory transfers from one location, or even assign specific employees access to complete inventory transfers, to ensure you have maximum control over the purchasing process. Erply also gives the ability to assign user rights to specific employees. If a business has 10 locations but only wants HQ to control how inventory is managed across the board, Erply can be configured to only allow certain employees access to purchase orders. Doing so eliminates any potential miscommunications that can happen between workers.