Fulfilling Sales Orders

– Lets Make E-B2B and EDI a Business Standard!

It’s pretty hard to imagine a more important task for a wholesaler than managing customer orders. All information sharing must be clearly directed and well-structured because employees from different fields are involved in the process. Salesmen are interested in solid delivery periods and purchasing managers are trying to find the right balance between stock and order quantity. Don’t forget, the accounting department also needs to have an overview of cancelled orders and delivery agreements made with the customers.

Receiving Sales Orders

[caption id="attachment_1326" align="alignnone" width="600"]

PO[/caption] Wholesalers are wishing for a situation where sales orders can come in electronically; meet exact client needs and inventory are always in stock. If the company has implemented a B2B online ordering environment, it’s possible to achieve a situation where customers actually order through online channels. A bonus is the possibility to copy previous orders, invoice, match similar products and combine various products. In case the client wishes to make the order in the business software used daily not via online ordering environment then electronic data interchange (EDI) will be handy. For this reason, some mediation firms offer a convenient alternative, but in the end, this will be more expensive than using an EDI interchange between partners. Nowadays, the problem isn’t the lack of technical solutions, but the unwillingness of old business software to cooperate when exchanging purchase and sale orders.

Filling Orders

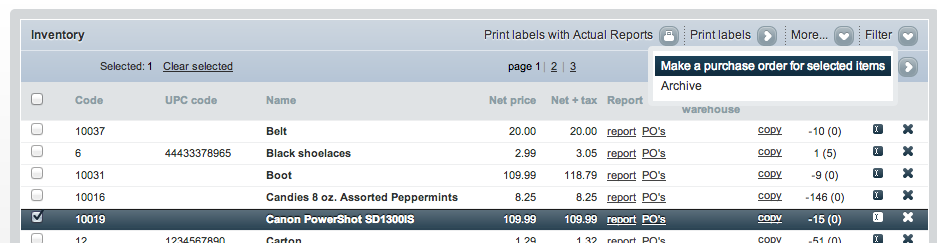

The number of wholesalers who fill their orders based on current stock is decreasing. Increased competition is forcing to expand the range of goods and involve products in the portfolio that might stay in the stock longer than the time it takes to deliver them. In these situations, the delivery time is set based on the caterer and the client can choose goods from the stock or products that need delivery. The difference lies in the delivery time. This method is based on the connection between the caterer and the product and on the aggregated planning that involves all the warehouses. Modern business software

on the basis of sale orders automatically generates product-specific reservations, which are in turn converted into caterer-specific purchase orders through aggregated planning. The purchasing team just has to send prepared purchase orders to caterers. The caterer has to specify the delivery time, which is added to the purchase order during the same work process. At the same time, information about the delivery period is sent to a salesman who notifies the client concerning the changes. In an ideal situation, the sale orders are received electronically. They are converted into purchase orders when there is no stock. Caterer fills in the purchase order(s) and they are turned into a purchase invoice and based on that the inventory is created according to stock value. After that, the sale orders can be completed, if there are enough goods. The whole work process can be automated and by that rearranging the duties of salesmen. Their role is now mainly receiving sale orders. In the meantime, the purchasing team is responsible for acquiring goods. The warehouse team gets the packing information when there are enough products to fill in the order.

Challenges While Filling Sale Orders

Customer-based service process implies that the needs of the customer are taken into account and in best cases are even exceeded. Solving these situations set new terms for the handling of orders.

Situation 1

The client wishes to receive products that are in the warehous

e immediately and has to wait for the goods that have a longer delivery time. The prepayment has been made based on the order confirmation.

Solution

The software is adjusted in a way that allows the orders to be filled partially. This means the sale order is divided into two: one part is issued immediately and the other is booked. The sale order comes with two bills of delivery that show the prepayment. Afterward, a single combined invoice is created from the delivery notes, which also indicates to all related documents.

Situation 2

The purchase o

rder

has ten items, but one is missing the stock quantity. The client isn’t satisfied with a replacement and the missing product has to be ordered from the caterer. Due to the long delivery time, the salesman offers to fill the order partially, but the client refuses. The reason is that the client can’t use the products separately.

Solution

The modern business software allows a user to set an order-based delivery condition. This means that all the goods have to be delivered together even though some of them might be present in the warehouse. The present products are booked and deducted from the stock. In case the available stock is below a minimum amount, the purchasing team will order the necessary amount.